NICItA: Nonwoven Infusion for Composites as Impact tolerant Aviation-Structures

Motivation

The high energy consumption and process costs associated with prepreg autoclave have motivated us to explore alternative manufacturing methods. Resin transfer molding (RTM) is a promising candidate with its potential for producing high-quality parts while being more cost-effective and environmentally friendly. By investigating and optimizing the RTM process parameters and materials selection, we aim to develop a more efficient and sustainable manufacturing method that can enhance the quality and reliability of the final products.

Objective

Our objective is to develop a multi-component non-woven material that can improve the resin transfer molding (RTM) process in several ways. First, we aim to incorporate binder functionality into the non-woven material, eliminating the need for additional binder materials. Second, we plan to include infusion functionality in the non-woven material to enable a faster and more stable process. Finally, we aim to enhance impact properties of the final product through the inclusion of an interleaf-layer, resulting in an improved overall product quality. By achieving these objectives, we hope to contribute to the development of more efficient and cost-effective manufacturing methods, while also improving the performance and quality of the final products.

Manufacturing

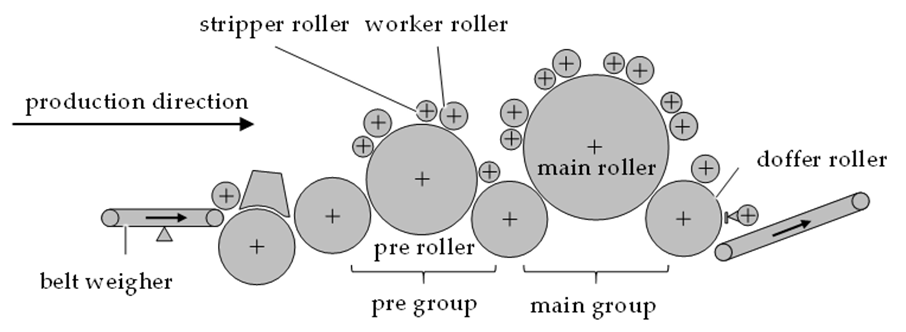

Our goal in manufacturing is to produce homogenous non-woven materials with a low areal weight of 20-40 gsm. To achieve this, we follow a workflow that begins with fibre mixing and preparation, ensuring even distribution of the different fibre types. Next, we use a carding machine to produce homogenous non-woven fabrics, which are then wound and stored. The final step involves thermal consolidation, which improves the handling and infusion functionality of the material.

Figure A. Schematic representation of the carding machine

Figure B. Different non-woven qualities (l) bad quality (m) improved quality (r) good quality

Project Results

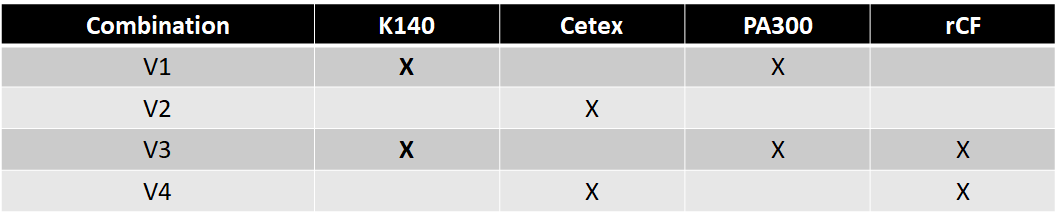

Binder & Preforming

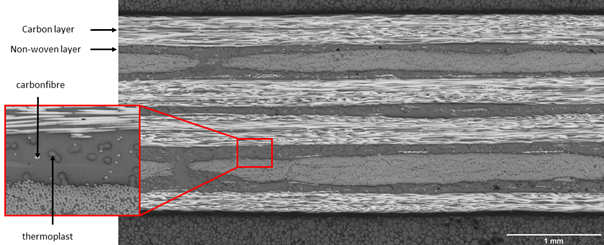

In our results, we found that K140 is a superior binder material compared to Cetex due to its different melting characteristics. We also observed that preform temperature has a significant impact on the results, and a higher share of binder materials leads to improved preform stability. Shown in Figures C and D.

Figure C Non-woven fabrics integrated between the NCF layers

Infusion

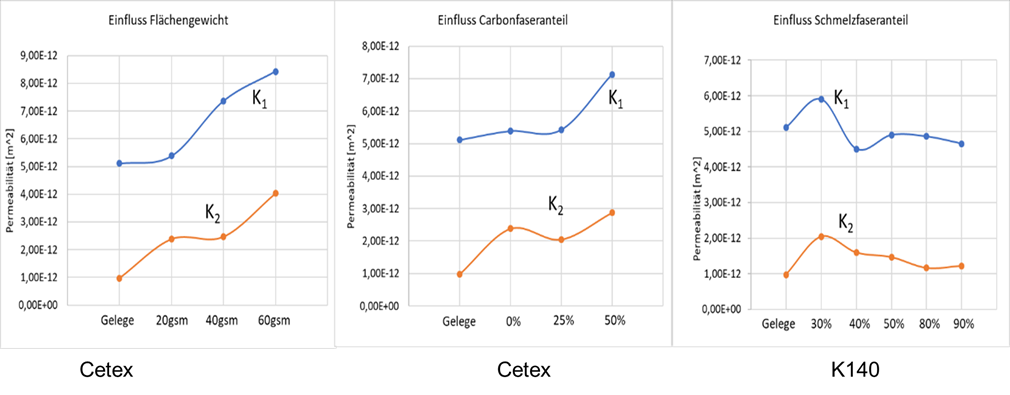

In our study, we performed permeability measurements using a 2D radial flow method for different fibre volume contents, as shown in Figure F. We compared pure carbon NCF with NCF that had non-woven between each layer and found that permeability improves with a higher areal weight of the non-woven and a higher share of rCF. However, we also observed that permeability degrades with a higher amount of melting fibre (K140). Furthermore, we found that Cetex is a superior permeability improvement material compared to K140.

Figure F. Comparing different influences on the permeability for 1 and 2 direction • Areal weight • Share of rCF • Share of melting fibre

Impact

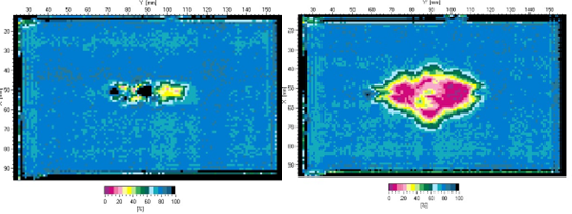

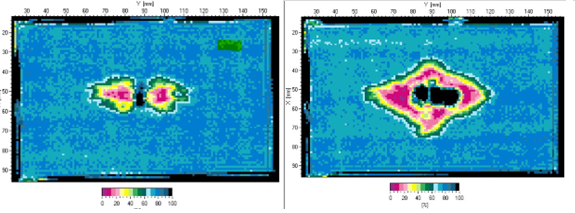

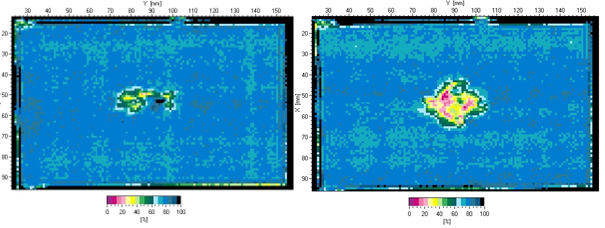

Both K140 and Cetex materials improved the impact response, with K140 performing slightly better than Cetex. We also determined that the multi-component non-woven material can be optimized by adjusting the weight percent of the fibre compositions and the areal weight to achieve the desired impact properties. Shown in Figures G, H and I.

Figure G: (l) pure carbon NCF- 8 Joule Impact, (r) pure carbon NCF – 16 Joule Impact

Figure H: (l) carbon-NCF + Cetex/rCF (50/50), 40gsm, 8 Joule Impact, (r) carbon-NCF + Cetex/rCF (50/50), 40gsm, 16 Joule Impact

Figure I: (l) carbon-NCF ++ K140/P300 (50/50), 40gsm -8 Joule Impact, (r) carbon-NCF ++ K140/P300 (50/50), 40gsm – 16 Joule Impact

Future Work

In our evaluation, we will consider and weight the experiments based on several factors, including binder/preform functionality, permeability improvement, and impact improvement. We are also currently analyzing the mechanical properties and will take them into account during the evaluation process. By analyzing these factors, we aim to provide a comprehensive assessment of the materials and processes studied. This will enable us to identify areas for further optimization and improvement, and guide future research directions in this field.

Acknowledgment

This work was developed within the scope of the project “Nonwoven Infusion for Composites as Impact tolerant Aviation-Structures” (Luftfahrtforschungsprogramm) supported by the Federal Ministry for Economic Affairs and Climate Action on the basis of a decision by the German Bundestag.

Funding agency:

Partner:

Your contact for the ITA Augsburg:

Felix Teichmann, M. Sc.

Wissenschaftlicher Mitarbeiter

Recycling & Verbundwerkstoffe

Tel.: +49 176 63713144

Your contact for the Fiber Institute, Bremen e.V.:

David Droste, M.Sc.

Tel.: +49 421 21859677

E-Mail: droste@faserinstitut.de